|

|

| MODEL KITS |

|

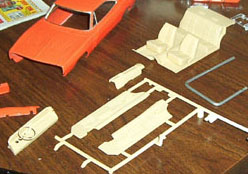

Revell-Monogram '69 Dodge Charger #2546

-or-

Revell-Monogram Pro Modeler '69 Dodge Charger R/T #5937

(Make sure this is the re-issued version, as the first

issue's body was designed incorrectly).

NOTE: Kit #2546 does not contain the interior

rollbar. You will have to create your own rollbar if this

kit is used. |

|

Correct American Racing Vector Rims from:

AMT/Ertl Eckler Corvette #8053

-or-

Older AMT kit #3102.

Both kits are discontinued. Watch for kits on eBay or

at retailers that sell discontinued kits. |

|

If

the Eckler Corvette model cannot be found, wheels and

tires from the AMT/Ertl General Lee kit will work, . They

are slightly less accurate, but will look fine if detailed

properly. |

| SPRAY PAINT |

|

|

Wheel Preparation:

Testors #1260 Dull Cote

Primer:

Testors #2937 Gray Primer

Body:

Testors #1628 Competition Orange

Interior:

Tamiya #TS-46 Light Sand (excellent shade of tan)

-or-

Testors #1249 Flat Black (if preferred)

Finish:

Testors #1261 Gloss Cote |

|

|

|

|

| BOTTLE PAINT |

|

|

Engine:

Testors Model Master #2732 Chrysler Engine Red

Turn Signals:

Testors Model Master #2723 Turn Signal Amber

Small Details:

Testors #1124 Green

Testors #1145 Gloss White

Testors #1146 Silver

Testors #1147 Gloss Black

Testors #1149 Flat Black |

| PAINT MARKERS |

|

|

Small Parts:

Testors #2546C Silver

Testors #2547C Black

Testors #2549C Flat Black |

| CEMENT |

|

|

Testors Model Master #8872C Precision Cement For

Plastic Models |

| TOOLS |

-Exacto Knife w/#11 blade (sharp for trimming Bare

Metal chrome foil)

-Pocket or hobby knife for scraping and trimming small

parts

-Paint brushes for bottle paints

-Round tip toothpics for painting small details |

| CHROME |

| -1

Sheet of Bare Metal brand Chrome Foil |

| SANDPAPER |

-1

sheet of 240-grit sandpaper

-1 sheet of 600-grit sandpaper |

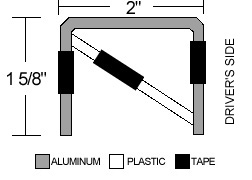

| PUSHBAR MATERIALS |

-1

sheet of .020" Evergreen brand Styrene

-1 package of 3/32" Styrene Tubing

-1 pushbar template from the January 2002 Scale Auto Magazine

(right click here, and click on "save target

as" to download the template) (Click here for pushbar instructions) |

| MISC. |

-Black electrical tape (for use as rollbar "padding").

I used tape that was 11/16" wide.

-White epoxy putty for plastic models (optional; for filling

side markers).

-1/8" diameter solid aluminum rod, at least 6" long (for

rollbar, if using kit #2546).

-Silicone adhesive (for securing rollbar, if using kit

#2546). |

|

NOTE: THE MAJORITY OF THE

MODEL IS BUILT ACCORDING TO THE KIT INSTRUCTIONS, BUT

READ ALL OF THE FOLLOWING MODIFICATIONS BEFORE BEGINNING!

|

|

|

|

1.

|

Spray vector rims with Dull Cote.

Let dry thoroughly.

|

|

2.

|

Using a toothpick, carefully paint the areas in

between the spokes flat black, as well as the wheel

centers. Take lots of time to avoid a sloppy job.

|

|

3.

|

When

assembling the wheels, use the wheel backs and tires provided

with the Eckler Corvette kit. Paint the inside of the

wheel backs black, as they show through the slots in the

rim.

|

|

|

|

1.

|

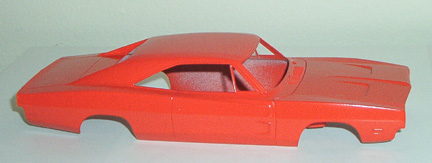

Sand

the wheel well chrome smooth. I used the edge of a pocket

knife blade to scrape the main excess, then finished with

600-grit sandpaper.

|

|

2.

|

Sand

the roof texture smooth, beginning with 240-grit and finishing

with 600-grit sandpaper. I began the process by carefully

scraping the "seams" with the edge of a pocket knife to

flatten them.

|

|

3.

|

OPTIONAL:

Use white epoxy putty for plastic models to fill in side

marker lights on fenders. Also fill back-up light holes

in rear valance. Sand filled areas smooth.

|

|

4.

|

Apply a coat of gray primer to the Body, Hood,

Radiator Core Support (part No. 35), Header Panel (part

No. 5), Front Valance (part No. 3) and Rear Panel &

Valance (part No. 4).

After drying, sand any necessary areas again. Apply a

second light coat of primer.

|

|

5.

|

Apply two coats of Competition Orange, letting

the paint dry thoroughly between coats. If necessary,

after the first coat, go over the body VERY lightly with

600-grit paper to even out any "orange peel." Also spray

the Radiator Core Support (part No. 35), Header Panel

(part No. 5), Front Valance (part No. 3) and Rear Panel

& Valance (part No. 4) Competition Orange.

|

|

6.

|

To

detail the taillight panel, paint above the bumper line

flat black. When dry, paint the chrome strip along the

top edge silver.

|

|

7.

|

After all paint is dry, spray Testors Gloss Cote

on body, hood, front valance and rear panel. Gloss Cote

over the flat black on the rear panel will give it a "satin"

look.

|

|

8.

|

When

paint has dried completely, apply Bare Metal chrome foil

to the trim areas. Follow the directions on the package.

With some patience, it produces impressive results.

|

|

9.

|

Paint underside of roof to match interior color,

and paint the underside of the hood and front inner fenders

gloss black. Paint both sides of the inner fenders (the

"under-hood" side and the outside, as seen when looking

into the wheel well.

|

|

10.

|

Carefully cut the "walrus teeth" off from either

side of the front license plate holder on the front bumper/grille

(part No. 7). Smooth out the area where they were cut,

and paint the scars silver (or cover with Bare Metal foil).

To

paint grille inserts flat black, first I masked the edges

with scotch tape, so the paint marker would only touch

the proper parts (see figure a).

Paint should cover the entire grille surface, including

the "cracks" around the edges (see figure b).

Optional: Before paint dries, use a toothpick

to clean paint off of grille trim and Charger emblem (see

figure c).

ASSEMBLY NOTE: When attaching front bumper to body later,

the bumper should be pushed back into the opening until

no chrome can be seen from the side of the car (except

for the side of the bumper) (see figure d). Photos

on the model box (kit #2546) are incorrect.

Figure a:

Figure b:

Figure c:

Figure d:

|

|

|

|

1.

|

Trace two side pieces from template (right-click

here and

"save target as" to download) onto sheet of styrene and

carefully cut them out.

|

|

2.

|

Cut two pieces of styrene tubing to length indicated

on template and glue them to one side piece using the

circles on the template as a guide. Make sure tubing

is perpendicular to the side piece (to avoid a crooked

assembly).

|

|

3.

|

When

glue is completely cured, glue the other side piece to

the ends of the tubing, making sure assembly is straight.

|

|

4.

|

Cut

two notches in the bottom of the Radiator Core Support

(part No. 35). The notches should be about 3/16" long

and about 1/16" wide (see figure e). This will

provide clearance for the pushbar when mounting it to

the frame later (see figure f).

Figure e:

Figure f:

|

D. ENGINE PREPARATION

Assemble per kit instructions, with the following

modifications:

|

|

1.

|

Grind the top of the carburetor (part No. 44) and

the underside of the air cleaner (part No. 61) to provide

hood clearance (engine may be slightly too tall if this

is not done).

|

|

2.

|

Paint air cleaner silver or black, depending on

preference (silver was most often used on the show),

"Magnum" decal also optional.

|

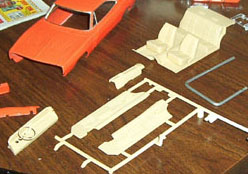

E. INTERIOR PREPARATION

Assemble per kit instructions,

with the following modifications:

|

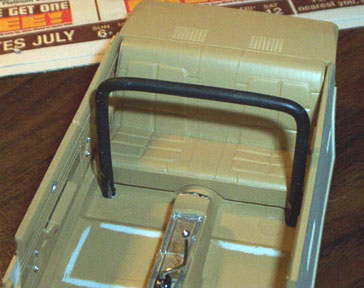

|

1.

|

Interior note: Part No. 86 (Interior

Brace) does not need to be installed on this model. It

serves no purpose.

Spray all interior pieces (floor, console, dashboard top,

dashboard, steering wheel, steering column, seats, seat

backs, headrests and door panels) light sand. (Flat black

is also an option, but tan is the "official" General Lee

interior color). When

dry, spray seats, dashboard, console, door panels, steering

wheel and steering column with gloss cote for a vinyl

appearance.

|

|

2.

|

Apply decals 8 & 9 (speedometer & tachometer)

according to instructions. Paint black and silver details

on instrument panel. Use Bare Metal foil on chrome trim

along door panels and trim around armrests. Paint window

cranks, steering wheel sections, console tray and other

details silver, using a toothpick.

Option: Install CB radio under the passenger

side of the dash. The one pictured below is from a "Daisy's

Jeep" kit.

Option: If you choose to have a black

interior, a nice touch is a woodgrain console. On the

interior pictured below, I used vinyl woodgrain stickers

that came with a computer desk.

|

|

|

|

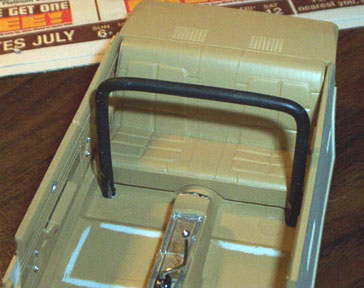

1.

|

Method 1: Trim the fire extinguisher

from the rollbar included with the Pro Modeler Charger

kit. Paint rollbar flat black.

Method 2: Bend a piece of 1/8" diameter

solid aluminum rod (available at hobby stores) into shape,

according to rollbar template below. Cut a plastic

section off one of the part "trees" (they are approximately

the same diameter as the aluminum rod) to make a diagonal

brace. Fasten brace using silicone adhesive.

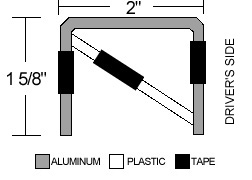

Rollbar Template

|

|

2.

|

Trim a piece of black electrical tape to about

1/2" wide and apply it to the driver's side of the rollbar,

about 1/4" from the top. Roll tape tightly around the

bar 2 or 3 times to simulate leather padding. Repeat

for the passenger side, applying tape just below where

the cross brace attaches. Roll a third, full-width (11/16")

piece around the cross brace, off-center toward passenger

side (see rollbar template above).

|

|

3.

|

Attach firewall, console, rear seat and door

panels to interior floor, per kit instructions, but

do not install front seats.

To install rollbar:

Method 1 (If using Pro Modeler kit with plastic rollbar

only): Locate the "shackles" (Parts No. 121)

that come with the Pro Modeler Charger. Attach each

one to the floor behind the front seats, and up against

the outer "ridge" in the floor. This will allow a "base"

for the Rollbar. Trim the pegs off the bottom of the

Rollbar (leaving the flat round bases). Cement the Rollbar

to the blocks.

Method 2 (If using aluminum constructed rollbar

only): Paint the bottom of each leg of the rollbar

black (or white, if using a black interior), and set

the rollbar in place (as close to the front of the rear

seat as possible) while paint is still wet. This will

leave marks where the legs will go. Using a 7/64" drill

bit, drill holes through the floor on your two marks

(see figure g). Using a hobby knife, open holes

a little at a time until rollbar legs fit into holes

(see figure h).

Remove rollbar and complete interior assembly, placing

the front seats as far forward as they will go.

When assembling interior section to chassis, use silicone

adhesive on the underside of the interior section, letting

adhesive get into rollbar holes. Place rollbar in holes

and adhere the interior section to the chassis. This

will anchor the rollbar in place.

Figure g:

Figure h (cross brace and padding omitted in

photo):

|

G. SUSPENSION MODIFICATIONS

Assemble per kit instructions,

with the following modifications:

|

| The following steps need

to be done to achieve the proper stance that is legendary

with the General Lee. |

|

1.

|

Trim

the pegs off the front spindles (parts No. 69 & 70)

and the rear axle housing (part No. 73), leaving the large,

flat areas. Wheel backs from the Eckler Corvette will

glue directly to the flat areas of the spindles and rear

axle. |

|

2.

|

Build front suspension as per kit instructions,

BEFORE PAINTING suspension parts or chassis. Pieces

will fit much easier, and this will eliminate having

to scrape areas to be cemented. Cover the flat areas

of the spindles (where the wheels will be glued) with

a piece of tape. After painting the chassis/front suspension

assembly, the tape can be removed to expose an unpainted

gluing surface (see pic below).

|

|

3.

|

Build rear suspension as per kit instructions,

but first, it's a good idea to fix a flaw in the model

kit:

Using a 1/16" drill bit, carefully drill new holes

in the leaf springs (parts No. 88) about 1/16" toward

the FRONT of the car, so when the Rear Axle Housing

(part No. 73) is attached, it sits closer to the front

of the car (this helps center the rear wheels in the

wheel wells) see pic below.

NOTE: The Drive Shaft (part No. 78) will need to be

shortened by 1/16" to allow for this adjustment. I simply

cut off the peg on the engine end of the drive shaft

and shaved the end down to the proper length.

|

|

4.

|

When cementing wheels to the front spindles and

rear axle, place model on its side. Scrape plating from

wheel backs, where they will contact the spindle/axle. Apply

cement generously to wheel back, and work glue repeatedly

with the edge of a toothpick until it becomes slightly

tacky. Place wheel in position, keeping top of rear

wheel barely visible below wheel well, and top of front

wheel just hidden above wheel well (see photo below

for correct stance). Make sure wheels are centered from

front to back in wheel wells. After one side is completely

cured, turn model over and repeat for other side.

Correct General Lee stance:

Older model, showing incorrect stance:

|

|

|

|

1.

|

Decals

For much more accurate, authentic-looking decals, order

the "01"s, Confederate Flag, Roof Lettering and Rear License

Plate decals from www.buildagenerallee.com. Specify

which decals you would like (i.e. Flag, 01s, Rear License

Plate). The flag is available in royal blue and navy blue

(earlier episode version).

For

the "General Lee" roof lettering, I designed the decal

on Photoshop with the proper size and font, and took my

design to my local sign shop. They printed the design

on clear decals.

|

|

2.

|

For the front Confederate Flag license plate decal,

I downloaded a picture of the flag from the internet

and re-sized it to measure roughly 1/2" wide by 1/4"

tall. I printed it on adhesive label paper and covered

it with a clear laminating sheet. You can then just

cut, peel and stick the decal to the front license plate.

|

|

3.

|

Optional:

If you are building a replica of the "first episode" Georgia

General Lee, that car had a "crossed flags" decal behind

the rear window. You can specify this in your order to

www.buildagenerallee.com, and they will include one.

|

|

|